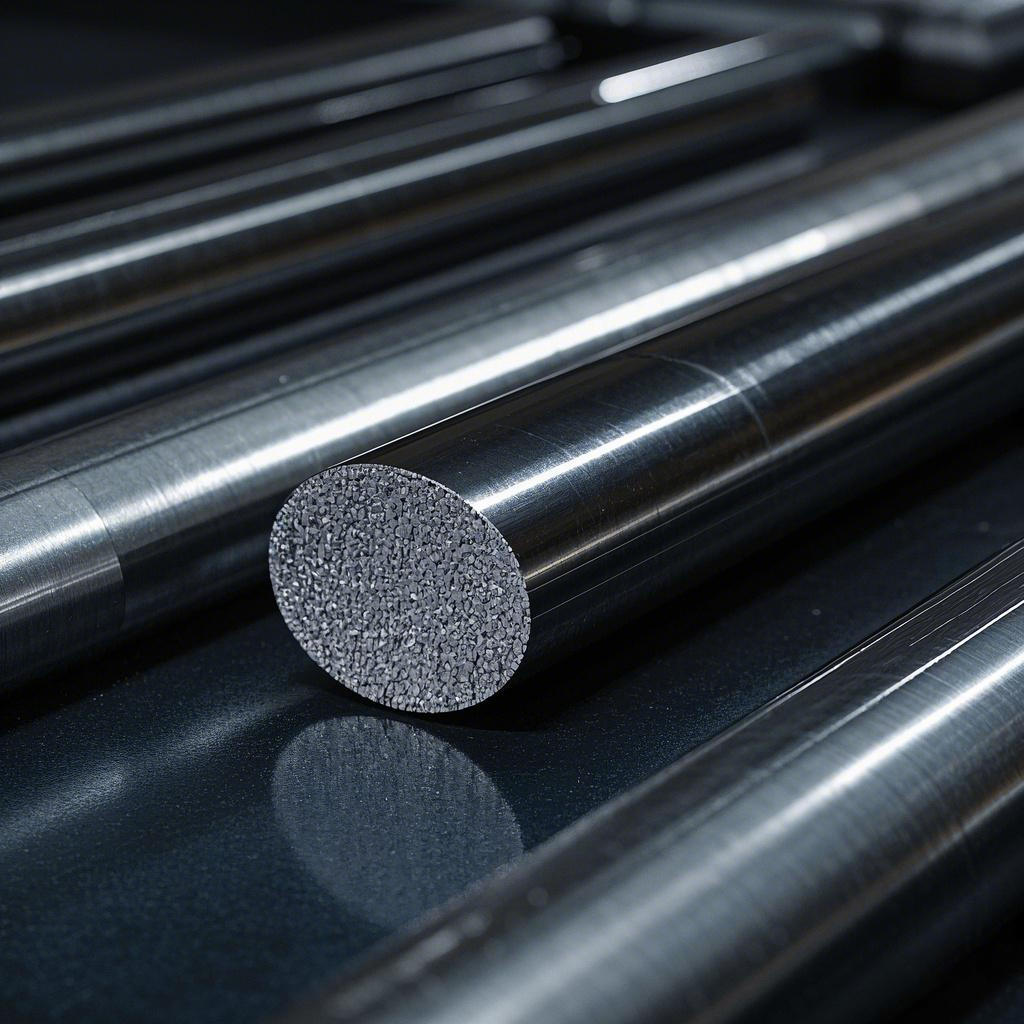

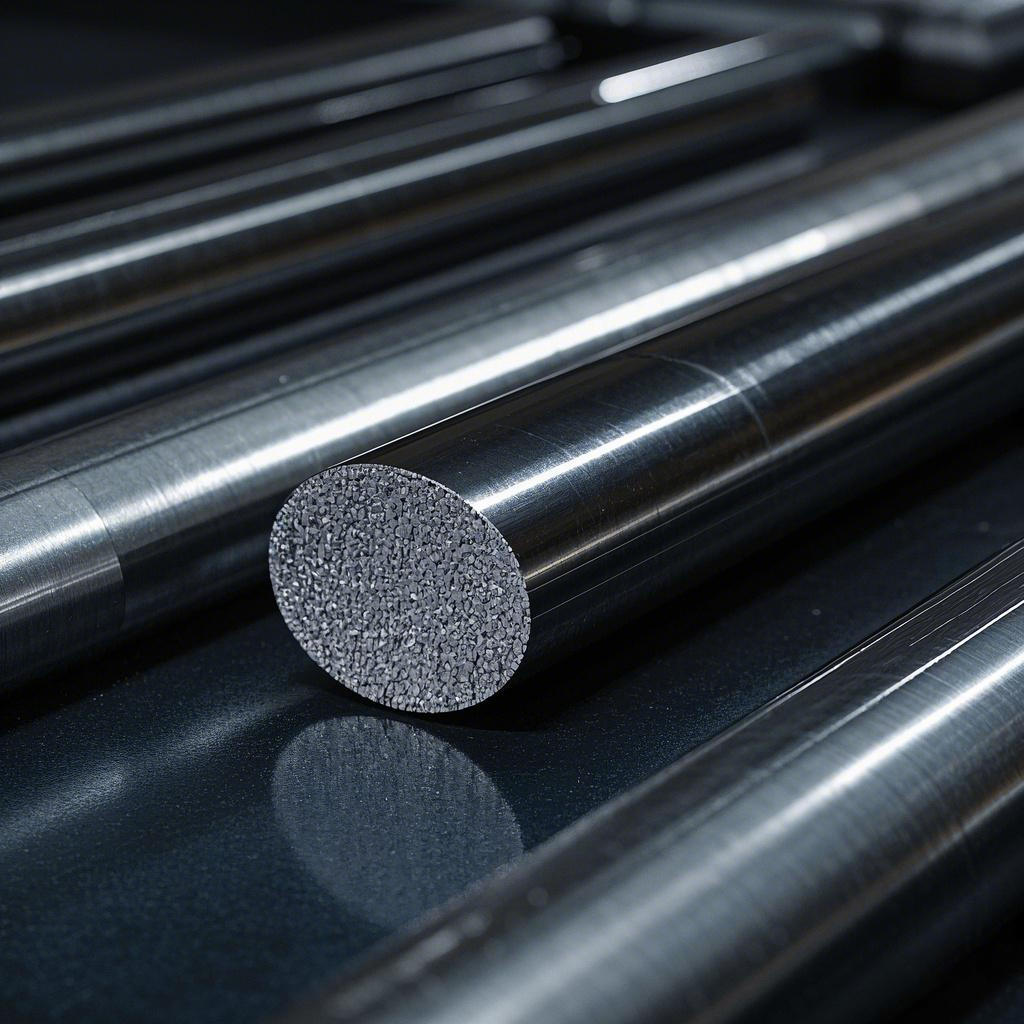

Hastelloy C-4/NS335/NS3305/N06455/2.4610/NiMo16Cr16Ti Alloy Bar For

Harsh Chemical Processing

Hastelloy C-4 (NS335, NS3305, N06455, 2.4610, NiMo16Cr16Ti) is a

nickel-molybdenum-chromium alloy known for its exceptional

resistance to high-temperature oxidation and aggressive chemical

environments. This alloy offers superior stability at elevated

temperatures (up to 1038°C) and excellent corrosion resistance in

strong oxidizing and reducing conditions, making it ideal for

chemical processing, power plants, and aerospace applications.

With a high molybdenum and chromium content, Hastelloy C-4 resists

pitting, stress corrosion cracking, and crevice corrosion. It also

has enhanced weldability and thermal stability due to its

controlled carbon and silicon content. Common forms include bars,

sheets, plates, and pipes, used in reactors, heat exchangers, and

acid production equipment.

This alloy is particularly valued for its mechanical strength and

oxidation resistance in extreme conditions, ensuring long-term

durability in harsh environments. Hastelloy C-4 bars are widely

used in industries requiring high performance and corrosion

resistance.

| Chemical Composition Wt.% | % | Fe | Cr | Cu | Ni | Ti | C | Mn | Si | Mo | Co |

| Min | | 14 | | Bal. |

| | | | 14 | |

| Max | 3 | 18 | 0.07 | Bal. | 0.7 | 0.15 | 1 | 0.08 | 17 | 2 |

| Physical Constants | Density(g/cm³) | 8.89 |

| Melting Range(℃) | 1325-1370 |

| AlloyState | Recovery Strength Reduction (RP0.2) N/mm2 | Tensile Strength Rm N/mm2) | Elongation A5% |

| Solid Solution State | 280 | 650 | 40 |

Trade Code

Hastelloy C-4 (also known as NS335, NS3305, N06455, 2.4610, and

NiMo16Cr16Ti) is a nickel-based corrosion-resistant alloy with

excellent properties. Here are its key features:

Key Features of Hastelloy C-4 Alloy Bar:

- Exceptional Corrosion Resistance

Excellent resistance to a wide range of severe chemical

environments, including strong oxidizers and reducing agents.

Superior resistance to pitting, crevice corrosion, and stress

corrosion cracking.

Excellent performance in high-temperature and acidic environments,

especially in nitric acid, sulfuric acid, and phosphoric acid.

- High-Temperature Stability

Maintains mechanical integrity and corrosion resistance up to

approximately 1038°C (1900°F).

Reduced tendency for grain boundary precipitation, making it ideal

for high-temperature applications.

- Excellent Mechanical Properties

High strength, toughness, and good ductility.

Good weldability with minimal risk of intergranular corrosion after

welding.

- Chemical Composition (Approximate values)

Nickel (Ni): Base (≈60%)

Molybdenum (Mo): 15-17%

Chromium (Cr): 14-18%

Iron (Fe): ≤3%

Titanium (Ti): 0.01-0.08%

Other elements: Carbon (C), Silicon (Si), Manganese (Mn), Cobalt

(Co), etc. in controlled amounts.

Hastelloy C-4 (also known as NS335, NS3305, N06455, 2.4610, and

NiMo16Cr16Ti) is a nickel-molybdenum-chromium alloy with excellent

corrosion resistance, particularly in strong oxidizing and reducing

environments. It offers superior thermal stability and resistance

to stress corrosion cracking, making it ideal for high-temperature

and aggressive chemical applications.

Applications of Hastelloy C-4 Alloy Bars

- Chemical Processing Industry

Used in heat exchangers, reactors, piping, and pressure vessels

exposed to corrosive chemicals like sulfuric, hydrochloric, and

phosphoric acids.

Ideal for environments with oxidizing and reducing agents, such as

nitric acid production.

- Pharmaceutical and Food Processing

Components in equipment requiring high corrosion resistance and

sanitary conditions.

Used in bio-processing reactors and sterilization systems.

- Aerospace and Marine Industries

Engine components and exhaust ducts subjected to extreme

temperatures and corrosive atmospheres.

Marine environments where resistance to seawater and harsh

chemicals is required.

Used in nuclear power plants for components exposed to radioactive

and highly corrosive conditions.

Gas turbines, boilers, and flue gas scrubbers.

- Pollution Control and Waste Treatment

Employed in scrubbers, ducts, and incinerators handling aggressive

industrial waste gases.

Flue gas desulfurization systems in coal-fired power plants.

- Heat Exchangers and Piping Systems

Used in high-temperature heat exchangers and piping for handling

hot, corrosive fluids.

Suitable for applications involving chlorinated or contaminated

environments.

- Medical and Laboratory Equipment

Utilized in medical implants and devices where high corrosion

resistance is necessary.

Used in laboratory equipment for handling harsh chemicals and

acids.

Hastelloy C-4’s ability to maintain mechanical integrity in extreme

conditions makes it a go-to material for industries demanding

high-performance corrosion-resistant alloys.